FACILITY

Crean room

Customer quality requirements are not only limited to accuracy, strength, and characteristics, but also high cleanliness. We meet high demands by cleaning, inspecting and packing screws in a clean room.

The washing machine has a strong commitment, and by adopting the horizontal transport method and the quick dumpling method for each cycle, it has achieved an epoch-making cleanliness for screw cleaning.

The cleaned product can be controlled for each product using a particle counter and ion chromatograph.

Clean room facilities

- Chemical polishing equipment

- Ultrasonic pure water cleaning equipment

- Particle Counter

- ion chromatograph

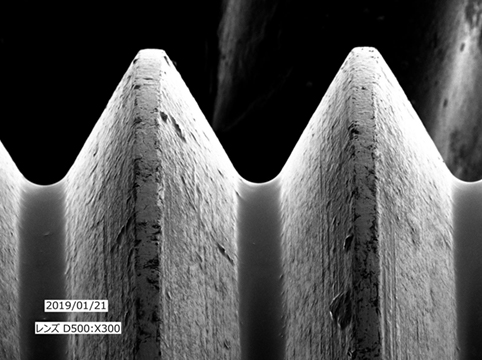

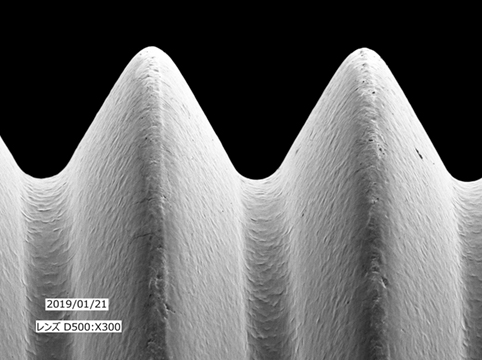

Changes due to chemical polishing of burrs and dust

Parts such as stainless steel have a glossy surface when chemically polished, and passivation improves corrosion resistance. Stainless steel parts are used in various fields such as medicine, semiconductors, batteries, automobiles, and HDD, but burrs, dust, and residues adhering to the surface have a bad influence on the quality.

By performing chemical polishing, it is possible to significantly reduce such burrs, dust, and residues.

- Before chemical polishing

- After chemical polishing

Work flow in the clean room

Ultrasonic pure water cleaning

By adopting the horizontal transport method and the quick dumpling method for each cycle, it has achieved an epoch-making cleanliness for screw cleaning.

Analysis / weighing

The cleaned product is measured for dust and weighed in a clean room.

Vacuum packing

To prevent dust generation during transportation,The product is clean vacuum packed.

Shipment

Deliver while maintaining high cleanliness.